Introduction

In this first in a series of articles on Engineering Document Management (EDM) in capital projects, I am going to discuss the goals and the key functional components to reduce cost and risk in capital projects.

Engineering Document Management Systems shall bring accuracy and control to facilitate fast and efficient information sharing and collaboration in capital projects.

Goals

The goal of Engineering Document Management Systems is to support capital projects in delivering the required documents completely and in quality to fulfill each milestone of a capital project on time.

That means that EDM Systems are aiming to achieve the following:

Optimize document control in complex projects that are planned with thousands of documents and drawings.

Manage collaboration of hundreds of project members and contractors who are working across the globe.

Accelerate review and approval processes of documents to comply with SOPs and regulations.

Control that contractors and suppliers deliver document revisions on time and on quality.

Deliver project documents on time to the customer to ensure sign-off and payment.

Mapping project documentation to tags and assets to ensure a seamless handover of information from engineering projects to operation and maintenance.

When you speak with professionals involved in large capital projects you soon discover that literally every issue has a document management component to it. There are so many different documents in different revisions at different states in the processes that must be worked on by so many different people. Keeping any document up to date and accurate is extremely difficult but essential for successful project execution.

EDM Systems provide a powerful set of functionalities developed for the specific needs of engineering and construction projects.

Document control processes

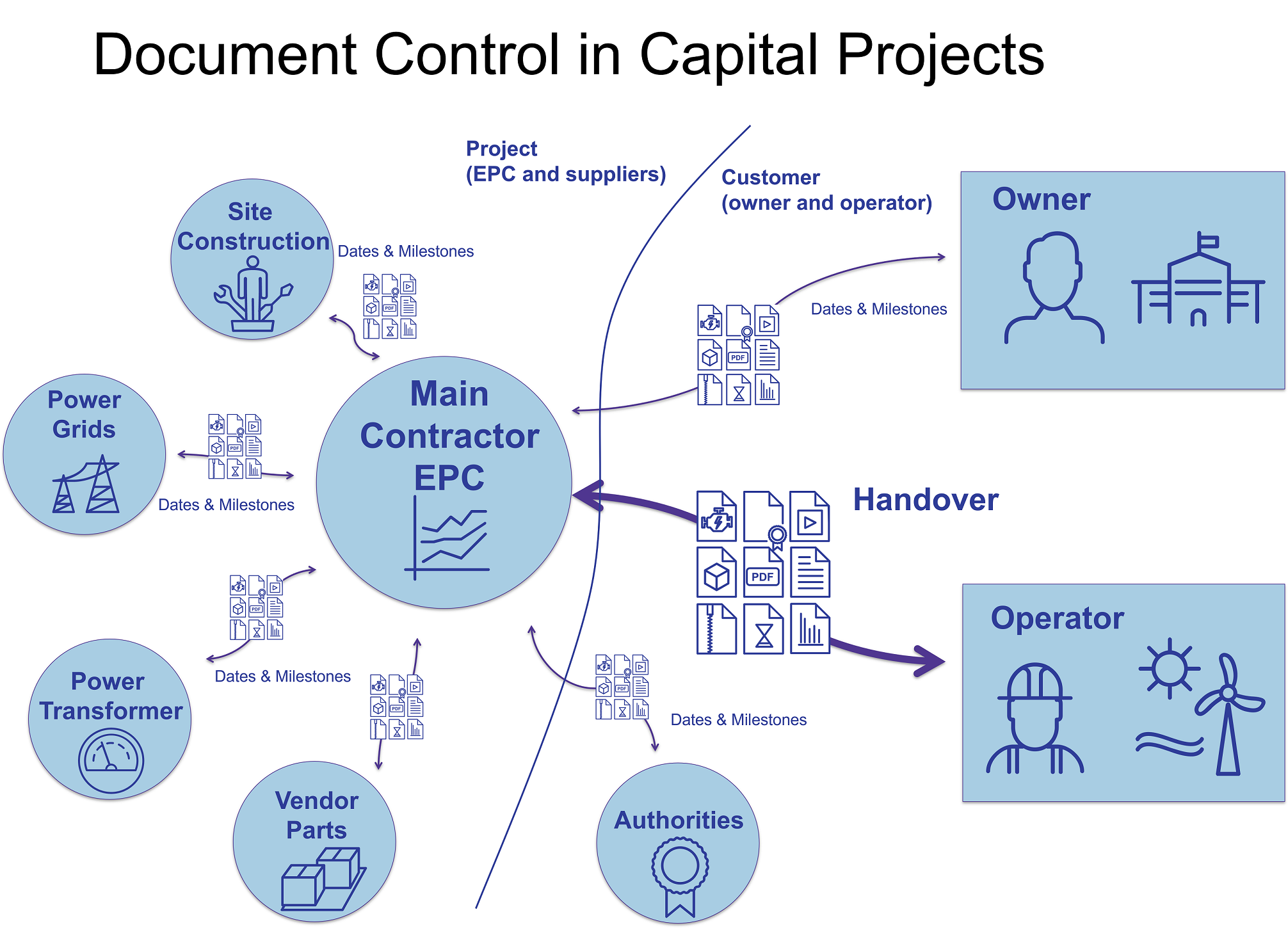

The simplified view of the above is that a main contractor (EPC) in a capital project relies on multiple suppliers to contribute documents that are consolidated by the EPC to fulfill the deliverables to their customers at every milestone. Dates and milestones determine when the EPC has to submit defined documents to the owner for approval, to authorities, or to the operator for handover. Derived from these dates and milestones from the customer, the EPC defines dates and milestones for their subcontractors, suppliers, and vendors.

The delivery and approval chain of documents from suppliers to the customer can be explained on the following diagram.

It explains that all supplier documents are managed in a Master Document Repository on the EPC´s EDM System but only some documents are planned to be submitted to the customer. And only approved revisions of those documents are submitted.

Key functional components

The comprehensive view requires explaining the key functional components that are needed to support this information flow in a controlled manner. See the next diagram and the following explanation to get a full overview of what EDM Systems are supposed to be capable of.

The diagram below lines out more details but still not all functionality that is commonly available in a state-of-the-art EDM System.

With large projects involving thousands of documents, it is all too easy for the wrong set of documentation to be used. Different parties are making changes to the versions of documents that are never properly reconciled. The inevitable result is inaccurate information causing the wrong work to take place. Reworks are costly and wasteful and lead to the risk of project overruns and penalties.

A central document repository for controlled documents (aka Master Document Repository) provides a "single source of the truth" for all controlled documents, where all documents are kept up-to-date and accurate and far easier to locate and access. The Master Document Repository always keeps the most recent approved revision of controlled documents and keeps track of which team, contractor, discipline, or work package is currently working on a new revision.

The identification and uniqueness of documents in the Master Document Register are supported by a document numbering system. This ensures that each controlled document has a unique document number which consists of document attributes and a counter. The Master Document Repository is the system that generates the document numbers upon request, and it is the only location that keeps the reference between supplier, EPC, and customer document numbers.

A list of all line items in the Master Document Repository we call Master Document List (aka. Master Document Register).

Revision Control with Project Workspaces

Design work takes place simultaneously which means that the creation and change of documents is a simultaneous process. As revisions happen, multiple versions are created that others are not aware of and can’t immediately access.

EDM Systems give engineers and contractors guidance and access to the documents they need to complete their work. They have edit permissions on those documents they have to create or change by adding a version. This happens by offering one or multiple project workspaces that reflect a particular work package of a project to the supplier to submit new documents or new versions of documents. When the package responsible engineer deems those documents to be ready, they push them into the review and approval process flow to be reviewed and, once approved checked in to the master document repository as a new revision. The next person to access the document from the Master Repository is guaranteed that this is the latest approved revision. With this process of sign out – change – approve – sign in a new revision, the document quality and integrity are maintained throughout the document lifecycles.

Document planning

Before the start of a capital project the investor and the owner/operator define the list of documents to be delivered by the EPC. The EPC defines the list of document deliverables for each of their suppliers to control the completeness of package deliverables. Approved documents represent the fulfillment of package milestones in a capital project. Document planning in an engineering capital project provides the ability to control the completeness and due dates of all document deliverables, regardless of whether the documents must be sent out or are expected to be received as inbound documents from suppliers.

A prerequisite to controlling the completeness of documents to be delivered by the EPC as part of an engineering capital project is the planning of document deliverables in a Master Document List (MDL). EDM Systems provide the functionality to generate Master Document Lists (aka. Master Document Repositories). That gives the ability to keep project deliverables on time, in scope, and at the highest quality.

State Control and Progress Reporting

Inefficient processes, whether manual or digital add cost and delay. Without effective process flows, process state control, and progress reporting the project delivery is not under control. Project managers and document controllers have no overview if documents of a delivery package have been accomplished by the responsible person and reviewed/approved by the accountable discipline lead.

The financial success of an engineering or construction project depends on the timely submission and acceptance of documents at all stages of the project.

This is true for all project milestones. If the document quality is poor or the information inaccurate, the project milestone may not be accepted which leads to costly rework and potentially even more costly contractual penalties.

Engineering documents are deliverables of work packages in the WBS of engineering projects. The delivery date of the documents is similar or the same as of the engineering package itself. Document expediting and progress tracking in accordance with the project plan in Primavera or SAP PLM is essential to keep the project on time and in budget.

Building Information Modelling (BIM)

Over the past few years engineering companies and engineering departments of owner/operators have been introducing BIM to improve efficiency in collaboration and quality in delivering construction projects. Engineering Document Management is an important pillar in the BIM methodology which is based on regulations like ISO 19650. Companies who want to establish BIM standards or have already established the same have to consider a change in the way how engineering documents are currently treated. EDM Systems must be able to adopt BIM standards by supporting model information in a central repository (Common Data Environment). BIM manages the creation and exchange of asset information between the owner/operator, contractors, sub-contractors, suppliers, and authorities. It introduces the concept of a Common Data Environment as a central repository of engineering data and documents which represent a model of the plant to be built. Stakeholders who work on subsets of the model can always refer to the model as a whole.

Collaboration with external Stakeholders

There are many stakeholders involved in construction and engineering projects. Owners and operators, contractors, suppliers, and authorities need the right information at the right time. In large capital projects, the team is likely to consist of several disciplines from several international contractors. The EDM System must be able to allow both, agile collaboration by sharing documents on an online platform as well as transactional exchange of approved, commented, and rejected documents as structured Transmittal packages.

Handover from engineering projects to operation and maintenance

At the commissioning of a plant, the documentation must be available for Operation and Maintenance (O&M). If not planned from the beginning of a capital project, the plant documentation will be handed over from the EPC in a way that is not prepared for O&M. Therefore, thousands of documents must be stored on a file server without any link to the asset structure, tags, equipment, or O&M processes on the asset management system.

As requested in standards like ISO 15926 and ISO 81346 for the process industry, the documentation handover process must connect the engineering and O&M documentation with technical objects on a plant, such as equipment or functional locations (units, sub-units, areas, or systems). This is only possible if

The engineering and O&M documents are planned from the beginning of the capital project in relation to asset tags and

The Asset Management System and EDM System are tightly integrated.

Summary

All the goals that Engineering Document Management Systems aim to achieve can be accomplished by the seven key functional solution components.

The Master Document Repository,

Project Workspaces and document revisions,

Document planning,

State control and progress reporting,

BIM and collaboration with contractors, suppliers, and owner/operators,

Handover from engineering projects to operation and maintenance.

Learn more about these key components in the following articles that will be published soon on this website.

Author: Jens Friehmelt is a Senior Manager in OpenText Professional Services EMEA leading an international team that combines multiple OpenText technologies to serve customers with best-practice solutions for Engineering, Construction, and Maintenance processes.

Reference: Read also similar content on OpenText Bogs https://blogs.opentext.com/how-to-reduce-cost-and-risk-in-capital-projects-2/

#EngineeringDocumentManagement #CapitalProjects #DocumentControl #DocumentController #opentext #ecm #extendedecm #AsBuilt #MoC #ManagementOfChange #AssetManagement #ProcessIndustry #OperationAndMaintenance #O&M #AssetLifecycleInformation #AssetLifecycleDocumentation #AssetDocumentManagement